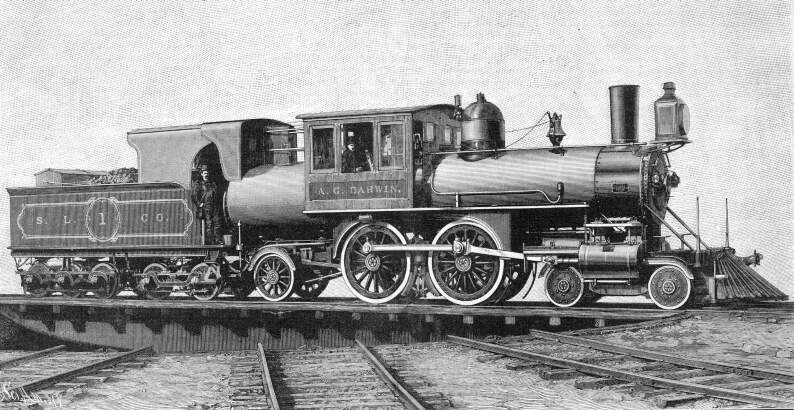

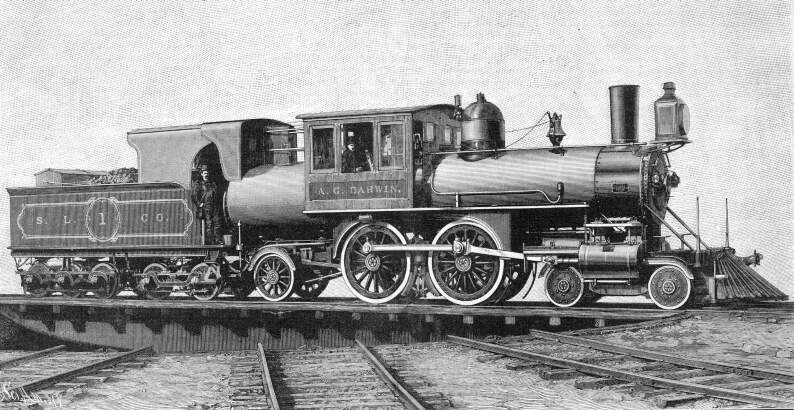

Manufactured by the Strong Locomotive Company

Scientific American - New York, January 12, 1889

(mirrored without permission from Railroad Extra at The Catskill Archive)

THE STRONG LOCOMOTIVE

The locomotive of the present day is but little different from the machine of thirty years ago. The old fashioned slide valve of the D type has been retained, the boiler has for many years been of the tubular character, of so definite construction that the term locomotive boiler represents a well recognized structure. For a long time locomotive boilers were noted for carrying high pressures, but now they are distanced in the race, even the large marine boilers on steamships equaling or exceeding them in this respect.

The Strong engine indicates a departure in the construction of locomotives that is quite radical. The boiler and valve gear are of original design, and the results already achieved appear to be well in advance of the usual practice. The engine we illustrate can main- a speed, it is claimed, of 60 miles an hour, and is credited with a mile in 47 seconds. These results were obtained while it was new, and not fairly limbered up.

The boiler is bifurcated at the fire box end, forming two fire chambers and contains two grates. The fire boxes are joined to a single combustion chamber which forms the next division of the boiler. These parts are made of corrugated steel plates with welded longitudinal seams. The combustion chamber abuts against the tube sheet Forward of this comes the main body of the boiler, traversed by the tubes, 235 in number. The boiler shell incloses the two fire boxes and the combustion chamber being itself bifurcated. As far as possible, all the elements of the shell are cylindrical. The connecting portions between the barrel and the bifurcated portion are of generally spherical outline, so that the ends are the only at portions. A flexible shell exposed to internal pressure would naturally take the cylindrical and spherical contour. Thus the steam pressure does not tend to change the shape of the shell, but all the strains resolve themselves into tension, except of course for the flat heads. These are strengthened by gusset plates, but the tubes supply the principal element of bracing, otherwise the boiler is unstayed A man can have access to every portion of the interior around the fire boxes. By using flanged seams hand riveting can be dispensed with. Much of the shell can be shaped by hydraulic pressure.

The two fires co-operate in burning the fuel. On one grate a very hot thin fire is kept, while a new fire is burning on the other. The latter gives off imperfectly oxidized gases which enter the combustion chamber. There they meet the hot oxidizing flame from the other fire, and are completely consumed. The fires are made to alternate in these roles. Thus almost any kind of fuel can be burned by one engine. The absence of stays and crown bars gives the boiler a character of unity that adapts it to withstand the strains and jarring inevitably attendant upon its work. Where a boiler is to be subjected to torsional and transverse strains, as in locomotive practice every stay is an element of weakness, only admissible to enable the flat surfaces to stand the internal steam pressure.

The corrugated furnace chambers have, as our readers know, been extensively introduced in marine boilers. They have effected important economy in this service, as higher pressures can be carried than with the old style flat-sided structures. They have co-operated with the compound engine to bring down the coal consumption to the very low point it has now attained in good practice. Its introduction on a locomotive is a step in the right direction, comparable to compounding the cylinders.

By its peculiar valve, the Strong engine is supposed to do away with the necessity for this last step. They are of such large port-area that a very sharply defined cutoff can be obtained. There is no steam chest, but each cylinder is fitted with four valves, two exhaust and two steam valves. They are of gridiron type. The steam valve has ten parallel openings, each 4-5/8 inches long, giving a total port length of nearly four feet (46-1/4 inches). The four valves are worked by a single eccentric so that the usual link motion is not used. It is impossible to fully describe the details here. The general action is slow at the beginning of the movement until the cushioning of the exhaust end of the cylinder relieves the pressure, when the valve quickly completes its travel. This avoids much of the friction of valve motion, something which has proved a very serious source of loss of power in ordinary engines.

When the engine is working at 250 revolutions per minute, it is claimed that the initial cylinder pressure will be within two pounds of the boiler pressure. When all is in perfect adjustment, it can readily be seen that excellent results should be obtained. The small extent of valve travel, about 1-1/16 in., together with the large port-area, about 48 sq. in., is the cause of this perfection of action. Against it, however the point has been made that the least amount of lost motion would seriously affect its work. Yet it seems clear that it would be well worth while to watch the valve gear closely, and keep it in condition to avoid such defects, when it is remembered how much good is involved in its details.

Its general dimensions are as follows:

| Cylinders | 19 in. diam. by 24 in. stroke |

| Driving wheels | 68 in. diam. |

| Total weight of engine with boiler full and coal on grates | 138,000 lb. |

| Weight on both pairs of drivers | 72,000 ib. |

| Weight on forward truck | 34,000 lb. |

| Weight on trailing wheels | 32,000 lb. |

| Grate surface | 30 sq.ft. |

| Heating surface | 1,650 sq.ft. |

| Working pressure of steam | 160 lb. |

| Wheel base of drivers | 7 ft. |

| Total wheel base | 29 ft. |

| Height above track, clearing everything | 14 ft. |

| Total length of boiler | 31 ft. 5/16 in. |

It will be noticed that the engine has two cabs. A speaking tube is provided for communication between the fireman and engineer.

###